Aluminum isn’t just any element, think of it as the superhero of the periodic table. Why? Its remarkable weight advantage has been a game-changer for industries far and wide.

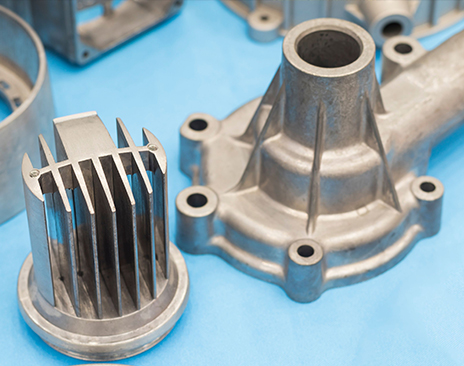

For over three decades, Cast & Alloys has harnessed this superhero to create feather-light and incredibly durable components. Their 30 years of expertise? That’s earned them the trust of a wide array of industries.

From the skillful world of cycling to the robust terrain of oil & gas, aluminum’s weight advantages are hard at work in countless ways.

In this blog, we will dive into how sectors like bicycle, motorcycle, automotive, railway, marine, and oil & gas are making the most out of aluminum. Ready to see how?

BICYCLES

In the world of bicycles, where every ounce matters, aluminum takes center stage. Aluminum cast and forged components by Cast & Alloys, ranging from minute connectors to integral parts, contribute to the overall lightweight design of bicycles.

Because aluminum is lighter than other materials, bikers may ride more smoothly and comfortably and with more agility and maneuverability. As the pedals turn effortlessly, the synergy of strength and lightness becomes evident.

MOTORCYCLES

Aluminum remains a dominant material, moving from bicycles’ pedal power to motorcycles’ thunderous engines. Cast & Alloys’ precision-forged components play a big role in enhancing the performance and agility of motorcycles.

In the world of motorcycles, where speed is paramount, the weight advantages of aluminum become a performance imperative. Aluminum parts are lighter than other materials, which helps with acceleration, braking, and general maneuverability. This makes riding on the open road more thrilling for riders.

AUTOMOTIVE INDUSTRY

Aluminum’s use in automotive engineering goes beyond just reducing weight. It’s about redefining how cars perform.

Aluminum is steering the development of lightweight and high-performance vehicles. This results in improved fuel efficiency, faster acceleration, and better handling, producing an unmatched driving experience and going beyond what we previously believed was feasible.

It’s changing how cars are built, from sleek sedans to powerful trucks. Reducing weight is essential in the automotive world, and aluminum helps in creating lightweight vehicles that perform better.

ELECTRIC VEHICLES

Aluminum has become a tactical ally in the electric vehicle (EV) era that is rapidly approaching, where weight is crucial. The lightweight nature of aluminum components compensates for the weight of batteries. Its remarkable strength has made it a cornerstone in the pursuit of effective and sustainable electric mobility.

Cast & Alloys’ expertise in Aluminum casted and forged components became instrumental in pushing the electric revolution forward, making EVs a more viable and attractive option for the future.

MARINE INDUSTRY

Embarking into the vast expanse of marine engineering, Aluminum continues to carve its niche. Components forged by Cast and alloys find a home in marine applications, where the weight advantages become a cornerstone of reliability. Due to its reduced weight and increased corrosion resistance, it is superior to all other metals and alloys.

Being lightweight has three main benefits: it can increase payload, expand equipment capacity, and require less power.

Cast & Alloys’ components are more than just their physical form; they create a smooth, harmonious symphony of functionality.

RAILWAYS

For the same reasons, Aluminum is growing more and more popular as the railway sector develops. Railway systems use a lot of aluminum casted and forged components, which leads to more efficient operations.

A lighter gearbox contributes to less unsprung mass and less wear and tear on rail components, making the railway system safer and more dependable while also extending its lifespan.

Apart from being lightweight, its corrosion resistance and thermal conductivity make it an ideal material for Railways.

OIL & GAS INDUSTRY

The working environment in the oil and gas sector is demanding and calls for precise and sturdy equipment. Being light in weight, Aluminum has always had the advantage of its strength-to-weight ratio and its ability to withstand corrosion is great. So the demand for Aluminum & its alloys has been constantly increasing in the manufacturing industry. Pipelines, drilling equipment, and storage containers can be made to be extremely strong, resistant to corrosion, and temperature-resistant by using particular alloys of aluminum.

It’s evident as we come to the end of our analysis of Aluminum’s weight benefits across a range of industries: this light metal is a catalyst for change rather than merely a material.

Cast & Alloys is leading the way in this Aluminum revolution with its commitment to precision and excellence. From bicycles to oil rigs, the weight advantages of Aluminum have been instrumental in shaping industries and driving progress.

Aluminum is a creative force that quietly shapes a future where strength and light coexist harmoniously as industries continue to change. With its knowledge of Aluminium casting and forging, Cast & Alloys acts as a guide in a world where every part—no matter how tiny—carries the weight of innovation and the potential for a lighter, brighter future. The journey continues, and we can anticipate a time when innovation and progress are fostered by Cast & Alloys’ expertise in Aluminum casting and forging.